3-Axis Milling

Low Volume Prototyping Solution

Material Selection

Aluminum 6061

-

6061 aluminum is an aluminum–magnesium–silicon alloy known for its high strength, lightweight properties, and corrosion resistance. It exhibits good tensile and yield strength, excellent fatigue performance, and dimensional stability, making it suitable for structural and precision applications. Common uses include aerospace components, automotive parts, marine fittings, industrial equipment, and custom fabrication. 6061 aluminum can also be anodized to enhance surface durability and provide additional corrosion protection.

-

Alloy Type: Aluminum–Magnesium–Silicon (Al-Mg-Si)

Density: ~2.70 g/cm³ (lightweight)

Tensile Strength: ~290 MPa (42,000 psi)

Yield Strength: ~240 MPa (35,000 psi)

Elongation at Break: 12–17% (good ductility)

Hardness: 95 HB (Brinell hardness)

Modulus of Elasticity: 68.9 GPa (10,000 ksi)

Thermal Conductivity: 167 W/m·K (excellent heat dissipation)

Melting Point: 582–652°C (1,080–1,205°F)

Corrosion Resistance: Excellent, can be anodized for extra protection

Applications: Aerospace parts, automotive components, marine fittings, high-performance structural components

Brass 360

-

Brass 360 is a copper–zinc alloy recognized for its corrosion resistance, strength, and wear resistance. It maintains dimensional stability and provides a smooth surface finish, making it suitable for precision components, mechanical fittings, musical instruments, and decorative hardware. Its natural golden appearance can also serve functional or aesthetic purposes in engineering and manufacturing applications.

-

Alloy Type: Copper–Zinc Alloy

Density: ~8.43 g/cm³

Tensile Strength: ~345–550 MPa (50,000–80,000 psi, depending on temper)

Yield Strength: ~150–300 MPa (22,000–44,000 psi)

Elongation at Break: 20–45% (good ductility)

Hardness: 80–120 HB (Brinell hardness, depending on temper)

Modulus of Elasticity: ~100 GPa (14,500 ksi)

Thermal Conductivity: 120–130 W/m·K

Melting Point: ~900–940°C (1,650–1,725°F)

Corrosion Resistance: Excellent; resistant to seawater and atmospheric corrosion

Applications: Precision components, mechanical fittings, musical instruments, decorative hardware, marine hardware, and electrical components

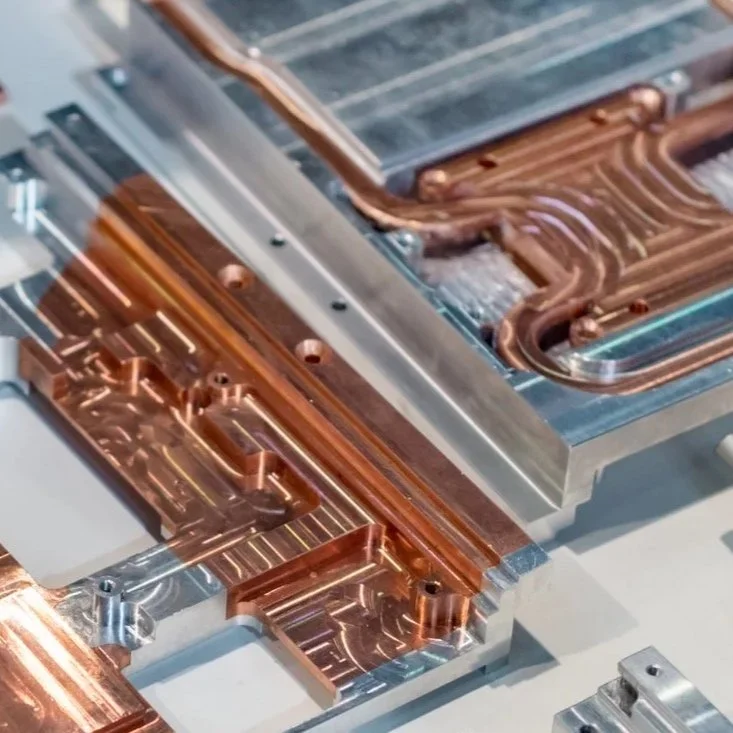

Copper C110

-

Copper C110 is a high-purity, electrolytic tough pitch (ETP) copper known for its excellent electrical and thermal conductivity, as well as its corrosion resistance and ductility. It maintains dimensional stability under stress and can be easily formed into a wide range of components. Common applications include electrical conductors, busbars, heat exchangers, plumbing, roofing, and decorative hardware, where reliable performance and long-term durability are required.

-

Alloy Type: Electrolytic Tough Pitch (ETP) Copper, 99.9% pure

Density: ~8.96 g/cm³

Tensile Strength: ~210–250 MPa (30,000–36,000 psi)

Yield Strength: ~70–210 MPa (10,000–30,000 psi, depending on temper)

Elongation at Break: 30–60% (excellent ductility)

Hardness: 40–110 HB (Brinell hardness, depending on temper)

Modulus of Elasticity: ~117 GPa (17,000 ksi)

Thermal Conductivity: ~390 W/m·K (excellent heat transfer)

Electrical Conductivity: ≥97% IACS (high electrical conductivity)

Melting Point: 1,085°C (1,985°F)

Corrosion Resistance: Excellent; naturally forms a protective oxide layer

Applications: Electrical conductors, busbars, heat exchangers, plumbing, roofing, and decorative components